Pallet Displays

A great Pallet Display must be strong, durable, and efficient while showcasing products. It needs to have enough structural integrity to withstand transport and handling, while maximizing product visibility. Displays must also be transport-friendly and sustainable. The pallet items below were designed with not only big-box requirements in mind but also ease of assembly and waste reduction.

This 4-side-shoppable pallet display for food pouches uses a simple Roll End Tray to separate the layers. Stacking support is provided using a 1-pc insert. Centered on the tray, 2 panels fold upwards to divide the products into 3 equal sections. The ends of the upright panels fold to create angled supports at the corners without needing tape or glue. This offers support not only at the corners but also along the heavier inside portion of the tray. The size was validated using CAPE Pack to ensure compliance with Big Box requirements.

This pallet display provides ample marketing real estate via the pallet skirt and graphics panel. The skirt is designed to fold up over the product to become its own shroud walls for shipping. The trays have built-in angled inserts with slots for product cards.

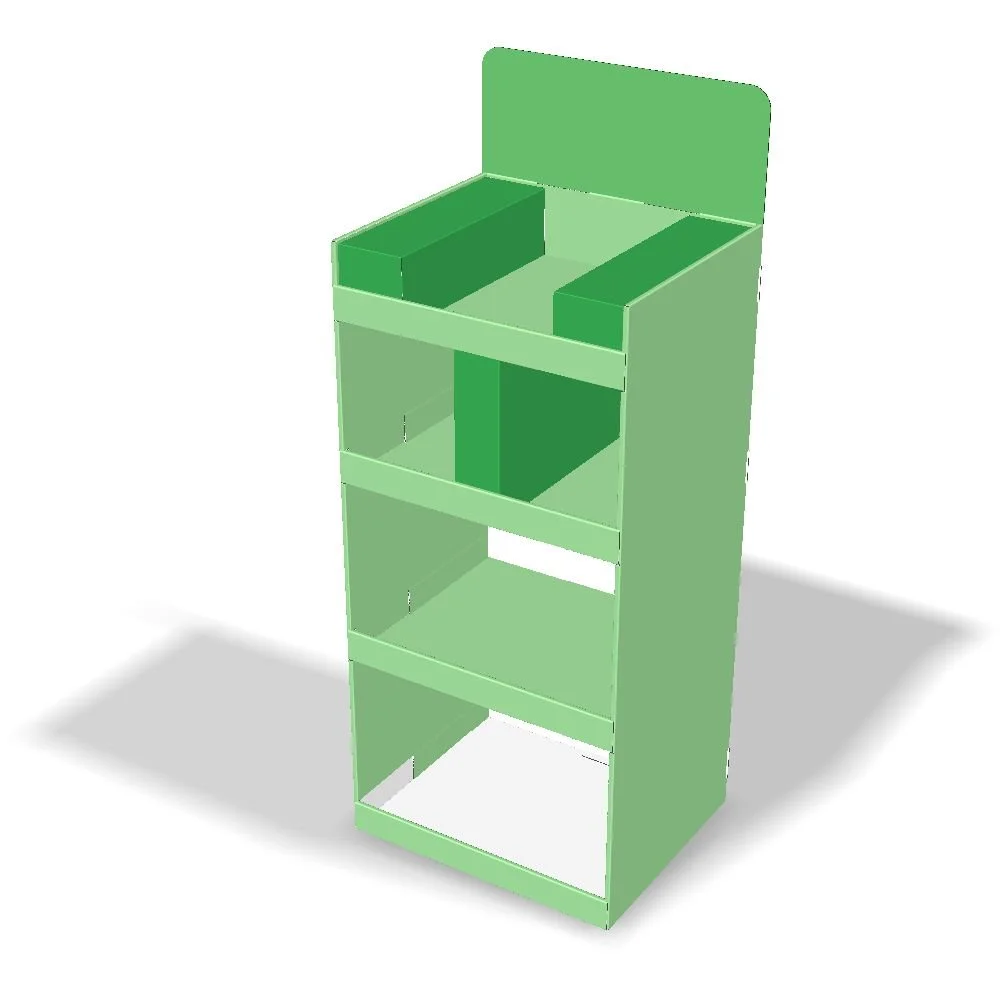

Sustainability was important to the customer so it played a part in designing this quarter-pallet display. The design utilizes lock tabs and friction instead of plastic clips, PSA, or glue. It also needed to be adaptable for a variety of products. Optional dividers could be placed inside the shelves, which offered additional options for product placement and also extra support for the shelf above.

This tray was designed to sustain refrigeration. All sides roll over to reduce the chance of moisture getting into the board, which would reduce structural stability. The board is coated and water-resistant adhesive (WRA) was utilized for the same reason. The product collars were designed for speed of hand-assembly. They use perf-scores instead of creases to reduce the "memory" of the board. There is a lock-tab closure in this design. An alternative could be PSA; while the speed of assembly would be helped a bit, lock tabs were preferred by this customer for waste-reduction reasons.

This demonstrates 3 options designed with the same prompt in mind - a pallet tray with shoulders that can assemble in 60s or less. From left to right, we see a Winglock, Econo-style, and a Bikini-style tray. All 3 have the same footprint as shown, making it easy for the customer to compare visual preference. All 3 designs are parametric so customer requests were easily accommodated with a simple input change.